To ensure optimal performance and longevity of X-ray grids, here are some best practices for handling and storage:

Proper cleaning: Regularly clean the device to remove dust, dirt, and other contaminants. Use a soft cloth or brush to gently wipe the grid’s surface, taking care not to damage the grid lines.

Avoid dropping or mishandling: Dropping or mishandling can cause misalignment or damage to the grid lines, impacting its performance.

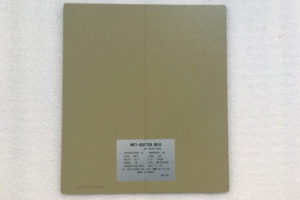

Use appropriate storage: Store the grid in a clean and dry environment, away from excessive heat, moisture, and direct sunlight. Use a protective case or cover to prevent dust, dirt, or accidental damage.

Avoid stacking heavy objects: Do not place heavy objects on top of the grid, as this can bend or distort the grid lines, affecting image quality.

Regular inspections: Periodically inspect the device for any signs of damage, such as bent or broken grid lines. If any damage is detected, the grid should be repaired or replaced to maintain optimal performance.

Follow manufacturer’s guidelines: Adhere to the manufacturer’s instructions for handling, cleaning, and storage of X-ray grids. This ensures that you follow the specific recommendations for the particular grid model you are using.

By following these best practices, you can help ensure that your X-ray grid maintains its performance and longevity, resulting in high-quality imaging results. Whatsapp:+86 18953679166. Email: service@newheek.com

Author:X Ray Grids Maker

Tel: +86 18953679166

Email: service@newheek.com

Company: Weifang Newheek Electronic Tech Co., Ltd.

Address: E Building of Future Star Scientific Innovation Industrial Zone of No.957 Wolong East Street, Yulong Community, Xincheng Sub-District Office, Weifang Hi-tech Zone, Shandong Province, China